The use of CNC machinery has transformed the manufacturing industry. This is done by speeding up the precision achieved by computers in cutting, drilling, and shaping operations. These computer-controlled tools produce parts that are inaccurate when operated manually.

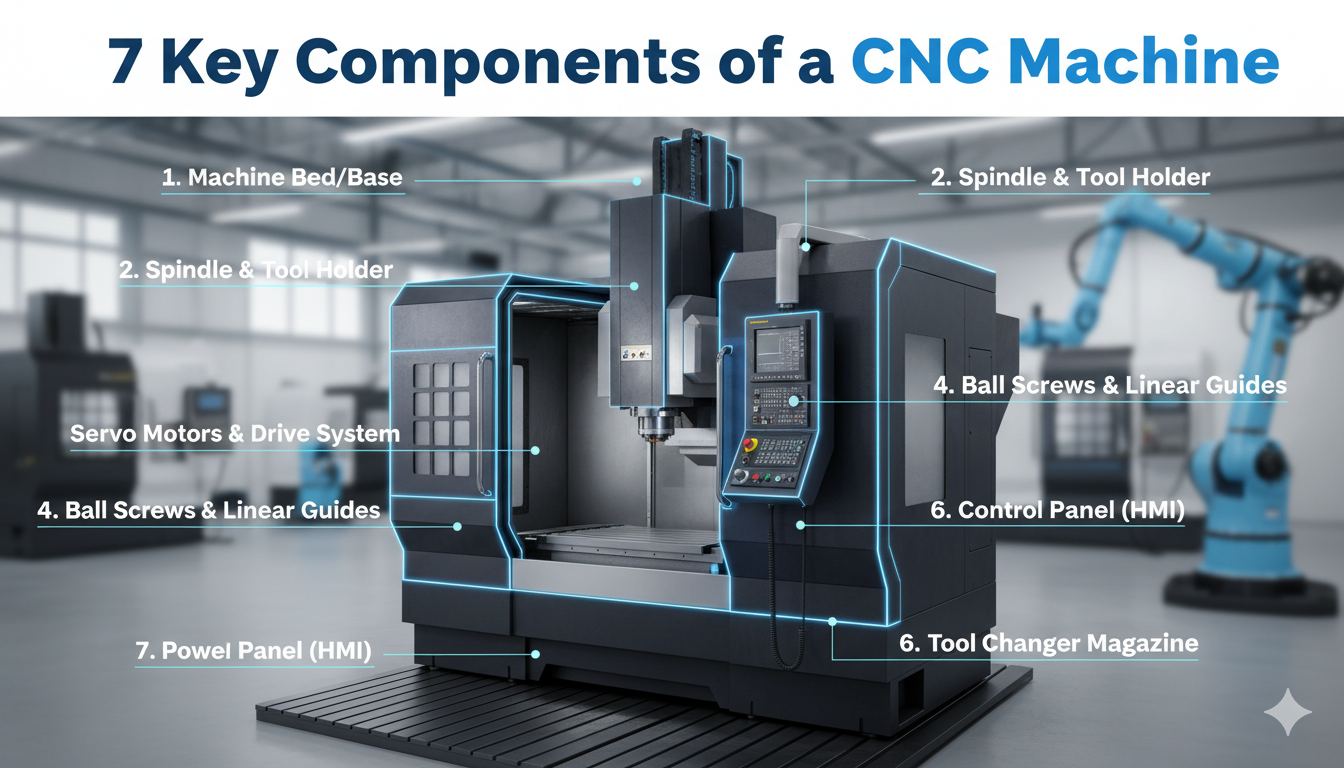

Knowledge of key CNC features helps operators, buyers, and specialists understand how these advanced systems work. All the elements contribute to the machine's overall performance and capabilities.

What the Control System Does

The control system acts as the brain of a CNC machine and controls all the operations. This computer executes digital instructions and drives the components' movements. The programming code is interpreted by the controller and translated into specific machine actions. The machine cannot operate without a control system.

The CNC unit is the specialized computer hardware used in the manufacturing control process. This special-purpose system performs instructions much quickly than general-purpose computers. The unit is in constant contact with all machine parts. Smooth operations are guaranteed through real-time processing.

CNC machines operate by special software utilizing G-code and M-code programming languages. These codes denote the direction, the speed, and the movements of the machine. Modern systems are typically accompanied by user-friendly interfaces that simplify programming. There are also more advanced machines that are fed CAD files.

CNC machines are operated with control panels with screens, buttons, and switches. The new interfaces are operated through touchscreens that resemble tablets, making them easier to use. The interface provides machine status, programming information, and error messages. Easy interfaces save time during operator training.

Control systems include a variety of programs that enable rapid changes to parts. The number of programs and the complexity of the operations are dependent on the memory capacity. Contemporary systems have USB ports or network connections for transferring programs. Correct storage prevents workflow disruption.

The machine frame serves as the firm foundation for all the parts. The construction is rigid, preventing vibration and deflection during cutting. Frame stability directly influences machining accuracy and surface finish quality. Heavy-duty frames do not bend with cutting forces.

Cast iron or steel is used in most CNC frames to achieve maximum rigidity and vibration damping. Cast iron is more vibration-resistant than welded steel designs. There are also specialized machines that employ granite or polymer well bases. In the choice of material, cost and performance will be influenced.

The bottom platform that carries the workpiece and other parts is called the machine bed. Accurate component alignment is achieved through precision-ground shapes. The bed needs to remain stable and flat under varying weights. Quality beds preserve their precision during the years of use.

Vertical columns sustain the movement of the parts and provide the main alignment. These structures should withstand the bending forces during cutting. There is an influence on column design, the work envelope, and the machine's reach. The reinforcement supports heavy columns.

A spindle is a cutting tool that holds and rotates at specific speeds. It directs the motor's power to the cutting edge. Cutting quality and productivity are directly affected by spindle performance. This part undergoes significant wear, necessitating frequent servicing.

Depending on use, spindle speeds will go between hundreds and tens of thousands of RPM. The faster speeds are appropriate for finishing operations, and the slower speeds are for heavy cutting. Power ratings are used to test the amount of material the machine can remove. The ability to match spindles to job requirements will help achieve optimal performance.

Belt-driven spindles provide more space and less vibration for light work. Direct motor spindles deliver optimal power for heavy cutting. Specific machines are motorized, having embedded motors on the spindle. Both types are appropriate in various applications and at different costs.

Spindles have different tool holders, such as collets and tapers, as well as quick-change. The holding system should firmly hold tools during cutting, preventing any movement. Quick-change systems minimize set-ups between operations. Precision tool holders have runout tolerances.

Spindles generate significant heat, which requires cooling systems. Liquid or oil-mist cooling provides the correct working temperatures. A sufficient level of cooling prolongs a spindle's life and improves precision. Spindle failures are costly and can be avoided by maintenance of the cooling system.

Understanding Machine Axes

CNC machines allow motion along three axes, abbreviated X, Y, and Z. Horizontal movement to the right and left is typically depicted on the X-axis. The y-axis controls front-to-back movement. There is the Z-axis, which controls the up-down movement. Extra rotary axes allow more complex part geometries.

Precision-ground ways or linear guides have been introduced to smooth axis movement. Rotary motion is converted to linear motion using ball screws or rack-and-pinion drives. These elements need to be precise throughout the travel range. Quality motion systems ensure uniform part dimensions.

An accurate, controllable servo motor controls each axis. These motors respond immediately to controller commands and hold fine positions. Motors have encoders that provide position feedback to the control system. Closed-loop control helps to match commanded and actual positions.

Power amplifiers are used to increase control signals to drive servo motors with the required current. These electronics take low-power control signals and convert them into high-power drive signals for the motor. Responsiveness and smoothness of motion depend on the quality of the amplifiers. Protective measures against damage are built into new amplifiers.

Positioning accuracy is a factor that defines how accurately the machine moves to the desired commanded positions. Repeatability measures consistency. Sliding back to the same position repeatedly. Backlash compensation addresses the mechanical looseness in drive systems. Accuracy specifications provide a reference for the anticipated part tolerance.

Automatic tool changers (ATCs) automatically change cutting tools. The systems save radically on the turnaround time between operations. The ATCs range from simple to complex, from carousel designs to matrix systems. Quick tool changes promote productive machining time.

The tool magazine holds various tools that are automatically selected. Depending on the machine size, magazine capacities range from 10 to 100 or more tools. Structured storage ensures rapid access to tools at any time. Others installed have tools with identification to avoid mixing.

The tools go through the magazine and the spindle, physically moving on mechanical arms or turrets. The mechanism should be able to place tools in a proper and safe location. The change times range from seconds to minutes, depending on the system design. Dependability eliminates production failures.

In modern systems, a sensor automatically recognizes each tool or RFID tag. This will avoid the use of inappropriate tools that may ruin or lack quality. Tool life monitoring will alert when a replacement is required. Identification systems minimize operator errors.

Cutting fluid removes heat from the cutting area, preventing tool and part damage. Reducing tool wear and friction is also offered by lubricating coolant. Removal of chips using flushing keeps the coloring area visible in the cutting region and maintains quality. Correct circulation of coolants is necessary to achieve the best results.

Flood-type coolant systems spray out vast amounts throughout the cutting area. The through-spindle coolant provides high-pressure fluid at the cutting edge. Mist systems use little fluid, resulting in a fine spray. The various delivery modes support multiple use cases.

The coolant systems clean and reuse fluid, reducing waste and costs. Some filters maintain coolant quality by removing debris and chips. Coolant circulation occurs through pumps. Clean coolant helps prevent premature tool wear and preserve part quality.

The chip conveyors automatically remove the metal chips from the cutting zone. These systems eliminate chip accumulation, which can ruin parts or equipment. There are many types of conveyors compatible with a wide range of chip sizes and materials. Proper chip management ensures a clean working environment.

Regular coolant testing and maintenance help prevent bacterial growth and degradation. The level of concentration should be monitored and changed. Polluted coolant also produces corrosion and ineffectiveness. Improved maintenance increases the life of the coolant and tools.

The workpieces should remain completely unmoved during machining. Movement results in dimensional errors and a poor surface finish. Secure holding also protects the operator from part ejection. Work holding has a significant influence on machining quality.

Milling vises are flexible for work holding numerous shapes and sizes of parts. The irregular components are fixed onto the machine tables using clamps. Using proper clamping ensures parts are unlikely to be distorted and remain secure. The designs apply to different uses.

Particular parts are always stored in custom fixtures used to make runs of parts. Such high-precision tools ensure consistent part positioning. Fixtures reduce assembly time and improve accuracy. In large-volume production, the cost of investing in fixtures will be recovered.

Chucks on turning centers hold cylindrical workpieces. Three-jaw chucks center automatically, and four-jaw ones can be mounted on an offset. Collet chucks are the most accurate when gripping and doing precision work. The selection of Chuck is based on the part's geometry.

Rotary machines are used to cut many sides of parts without reloading. Indexers are geared to turn to set positions with full-rotary tables, providing continuous rotation. These attachments give a machine a broadened capability. Rotary positioning is needed in complex parts.

CNC machines have seven Components that are in sync with each other. These are the main components to properly select, operate, and maintain to ensure the precision and productivity of CNC machines in modern manufacturing.

The use of CNC machinery has transformed the manufacturing i...

READ FULL